Ford Fuel Injection

Hi, this site is for all that want to repair, upgrade, or swap to EFI.We can all find small articles and buy many thick books but until now there has been no one stop on-line site for EEC questions.After reading many books and finding all the articles (on-line and in magazines) I started to answer question for many people.These questions made me realize that there were no good on-line help sites; I hope everyone can come to this site and feel comfortable with their EEC vehicle.These pages will primarily detail Fords EEC-IV (with Ford Trucks), but will include principles from other EFI control systems and vehicles.I also plan on turning to EEC-V in the future, just as carbs are being swapped for EEC-IV, EEC-V will be the future.Lets not all start sweating, I've already started my EEC-V research, and I’m kind’a excited.The Ford EEC is very special, tested, and proved around the globe.It has been estimated that Ford has sold more computers than IBM & Apple combined.The EEC has been tough enough to survive Desert racing 125+MPH into rocks, and quick enough for Indy racing’s 200+MPH @ 14000 RPM.Enough facts, lets get to the reason your all here.

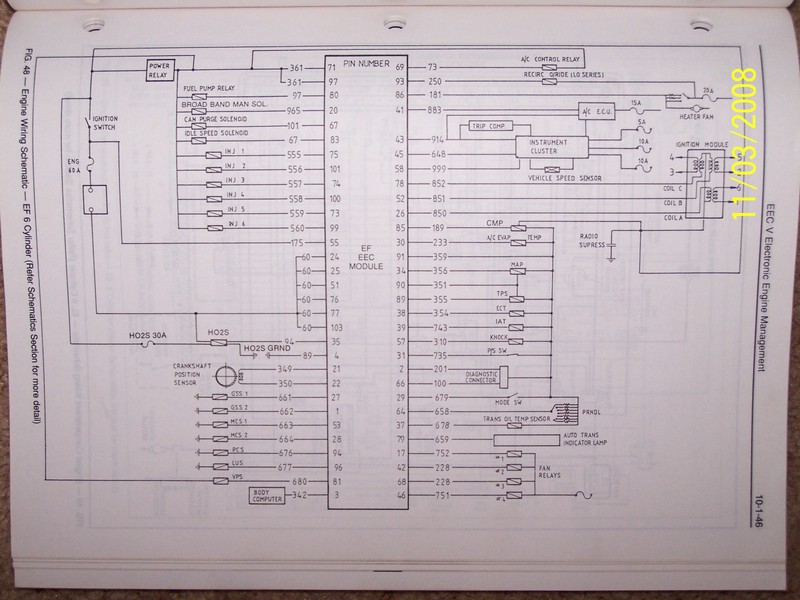

Starting EEC from Scratch. So you want that new fangled EFI thingy huh? EEC-IV might not be what you want; EEC-IV is the best “Factory” option we have but there are many different Fuel Injection systems out there. If you want to retain your cars every day streetabilty there are limiting factors that you will run into. Having a Mass Air Flow sensor is important for an every day streetcar. (, 05:35 PM) Gary M. Wrote: I have a lot of EEC-IV schematics, all on paper from Ford internal documents and manuals mostly. When they closed the Ford Microelectronics division in Colorado Springs, they just didn't care what we took home as we cleaned out our offices, and what we didn't take home, they dumpster-ed, so I tried to archive as much EEC-IV/V stuff as I could carry out. EEC-IV uses the same 60-pin connector as III, but one of the indexing tabs on the outside is offset. The internals of EEC are complex; Intel and Ford had a joint venture building EEC. EEC uses a custom Intel 8061 chip for its processing functions. This chip is modified only for EEC and is.

Every one say hello the EEC.Once hated by many, if understood properly she could be your best driving partner.Unlike previous technologies that would be affected by environment changes, EEC looks for these changes, reacts, and uses them for tuning.

SITE CONTENTS

EEC.What is it?

Electronic Engine Control.Remember this is the quick explanation for more click above.EEC-IV is a computer, it has a memory and chips and stuff inside.It “listens” to all the sensors, decides what the environment you’re driving in is like.It also listens to what the driver is doing and what you want to do.It decides what the best air to fuel mixture should be and what the timing should be at.It continues to listen making sure the outcome is what you and the EEC want it to be.Example, you smash the skinny peddle, she puts the mixture to around 12:1 and the timing around 32° BTDC.The engine revs up and you fly down the road, she checks to make sure the engine makes it to 4-5 thousand RPM and the car is speeding.Click below for further EEC philosophies and how to start:

Go to EEC

Sensors.Do I Need All of Them?

Umm?Yes and no.This is dependant on where you live and what you are trying to do.I do not use all the sensors designed for the EEC-IV system.But I’m not you.Sensors check tons of stuff:

·Engine position during rotation

·Whether the engine has too much timing

·The temperature of the incoming air

·The temperature of the engine

·How far you’re pushing the throttle

·If you’re pushing the brake or clutch

·What Sea level you’re at

·How much vacuum the engine has

·The amount of air it’s ingesting

·If it’s running rich or lean

·How fast the vehicle is going

·If the Air Conditioning is on

·If you’re using 1000 AMPS from the Alternator

WOW, that’s a lot to think about every 0.000001 seconds!OH wait, we don’t have to, EEC-IV will do all this for us.She decides what is happening now and what is going to happen 3 seconds from now.That’s smart, too bad it doesn’t always work as planed.Hmm, now we have a reason for this site.Click below for further sensor uses and testing:

Go to SENSORS

Actuators.Acting a Fool?

Actuators are the thing-a-ma-do-dads that gives fuel and spark to an otherwise really big paperweight.After sensing what is going on we now have to act on it.We need fuel, not just poured in, but measured amounts.We need timing advance, not just adjusted with the unreliable engine vacuum, but pre-planed programmed limits.What about pumping the throttle to keep it from stalling?HA, that’s covered too.OH NO, the government called, we have to make the exhaust smell lemon fresh.Now we need some exhaust recycled in the engine, the catalytic converter to burn more toxins, and the possibility to use cleaner fuels.CLEANER FUELS!We ain’t burning rice here kids; we’re talk’n Methanol, Natural Gas, Propane, and 100+ octane fuels (remember I said EEC-IV Indy cars).Click below for further Actuator uses and testing:

Tools.Does a hammer count?

Umm.Not unless you’re testing the knock sensor.You can’t change the jetting on these things.First we have to under stand why I said; “she could be your best driving partner.”EEC-IV listens to all the sensors, acts on them, and wants to tell you what’s wrong with her if there is a problem.There is already a great article about reading codes from an EEC-IV and I’m gon'a leave it alone.I've submitted some extra pictures and a more in-depth list of codes.Click here for that page.

Ford Eec Iv Repair

Most of the EEC-IV engine can be repaired with normal tools; there are only a few buys necessary for repair.There is also a wide verity of professional tools that are on the dream team list.Some can still be bought today while others are better found used.Remember that EEC-IV is OLD, EEC-V is the future, and probably outdated as I write this, an EEC-VI will be on the way in a few years.EEC-V is harder to deal with, but once the right tools are had and Ford releases some of its locked files, it will be a lot easier to use, trust me.Click below for all the cool tools:

Go to TOOLSContact Us

ã Copyright 2003 Fordfuelinjection.com, a division of RJM Injection.

Fordfuelinjection.com is not affiliated with Ford Motor Company.

Ford Engine TFI-IV System

Ford Eec Test

GENERAL INFORMATION

GENERAL TESTING

Spark Plug Wire Resistance

Ford Eec Iv Module

- Use spark plug wire removal pliers, or grasp firmly at the boot (not the wire itself) and remove the wires from the plugs, then remove the distributor cap.

- Measure the resistance through the distributor cap at that end. Resistance on these wires must not exceed 5,000 ohms per foot. Do not pierce any ignition wire for any reason. Measure only from the two ends.

TROUBLESHOOTING THE TFI-IV SYSTEM

- Disconnect the wiring harness connector from the TFI module; the connector tabs must be PUSHED to disengage the connector. Inspect the connector for damage, dirt, and corrosion.

- Attach the negative lead of a voltmeter to the base of the distributor. Attach the other voltmeter lead to a small straight pin. With the ignition switch in the RUN position, insert the straight pin into the No. 1 terminal of the TFI module connector. Note the voltage reading. With the ignition switch in the RUN position, move the straight pin to the No. 2 connector terminal. Again, note the voltage reading. Move the straight pin to the No. 3 connector terminal, then turn the ignition switch to the START position. Note the voltage reading then turn the ignition OFF .

- The voltage readings should all be at least 90 percent of the available battery voltage. If the readings are okay, proceed to the Stator Assembly and Module test. If any reading is less than 90 percent of the battery voltage, inspect the wiring, connectors, and/or ignition switch for defects. if the voltage is low only at the No. 1 terminal, proceed to the ignition coil primary voltage test.

- Remove the distributor from the engine.

- Remove the TFI module from the distributor.

- Inspect the distributor terminals, ground screw, and stator wiring for damage. Repair as necessary.

- Measure the resistance of the stator assembly, using an ohmmeter. If the ohmmeter reading is 800-975 ohms, the stator is okay, but the TFI module must be replaced. If the ohmmeter reading is less than 800 ohms or more than 975 ohms; the TFI module is okay, but the stator module must be replaced.

- Repair as necessary and install the TFI module and the distributor.